Everyone in the manufacturing business take utmost care of their products once they reach the final stage of the production and are ready to be stored or shipped to their customers. This is of course to do with the time and resources invested in the entire value chain and a damage at this stage of the value chain means it is not only a loss of material but also a loss of opportunity to earn profit. One of the industry where the products are often handled multiple times till the time it reaches its end use is the Auto Ancillary industry.

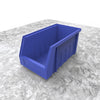

This means that the storage of these components produced require much more care. Since a few years now, the traditional corrugated boxes are now being replaced by the plastic crates.

Plastic Crates have become a really convenient option considering the wide variety of sizes that are available and also the convenience it offers like crates with handles or for that matter foldable crates which are a boon especially in case of reverse logistics.

The main reason why Crates have been popular in auto ancillary units specifically is because of the ability to create partitions inside the crate depending upon the component that needs to be stored. Such crates are commonly called as Partition Crates.

Over the past few years, auto ancillaries across the country in all of the 5 ancillary hubs (Chakan, Oragadam, NCR, Sanand and Pithampur) have become loyalists for a solution that not only stores and protects but also is a great tool to reduce material handling losses and thereby improving the overall profitability